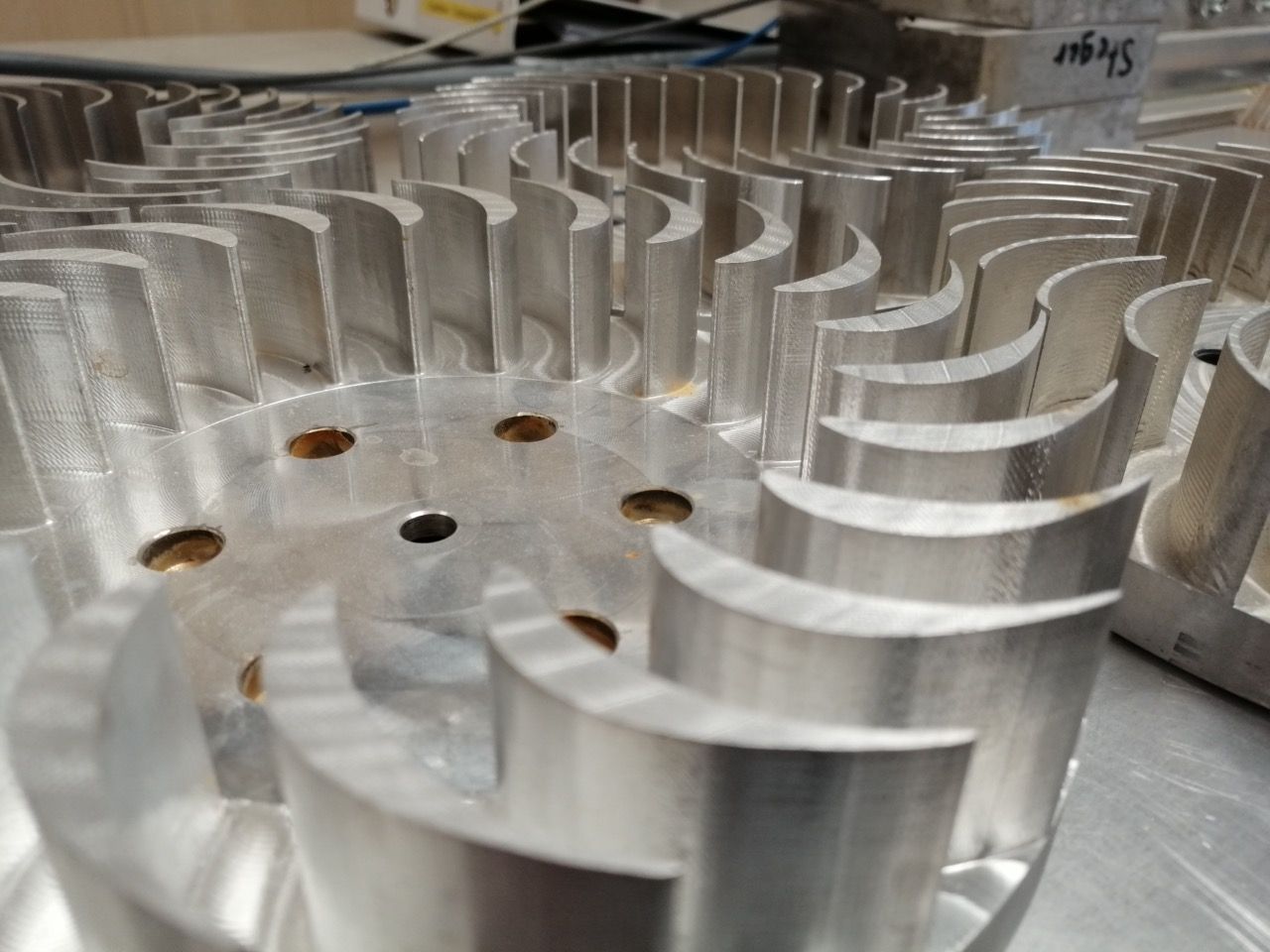

Using modern simulation software, geometries are optimised with the help of fluid mechanics, and high-stress components are checked by means of FEM calculation.

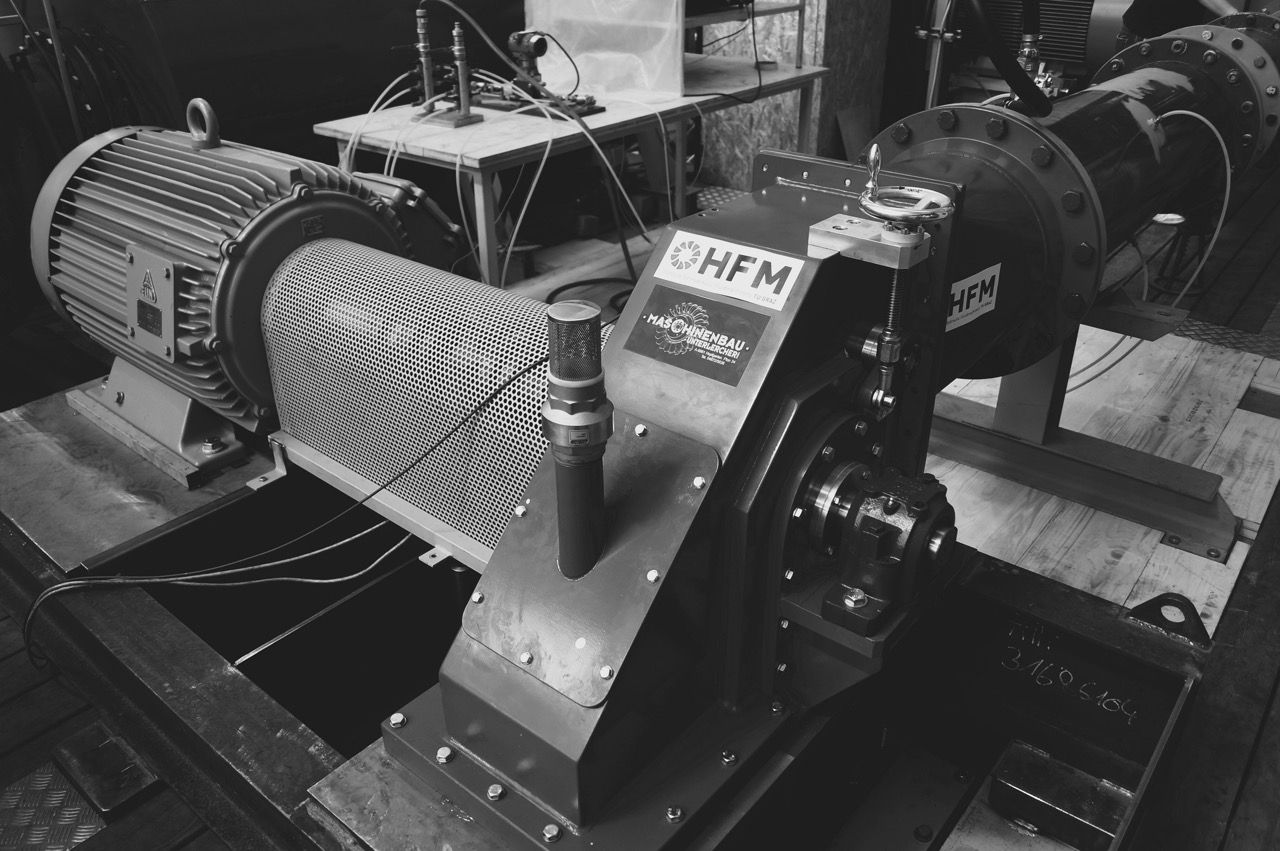

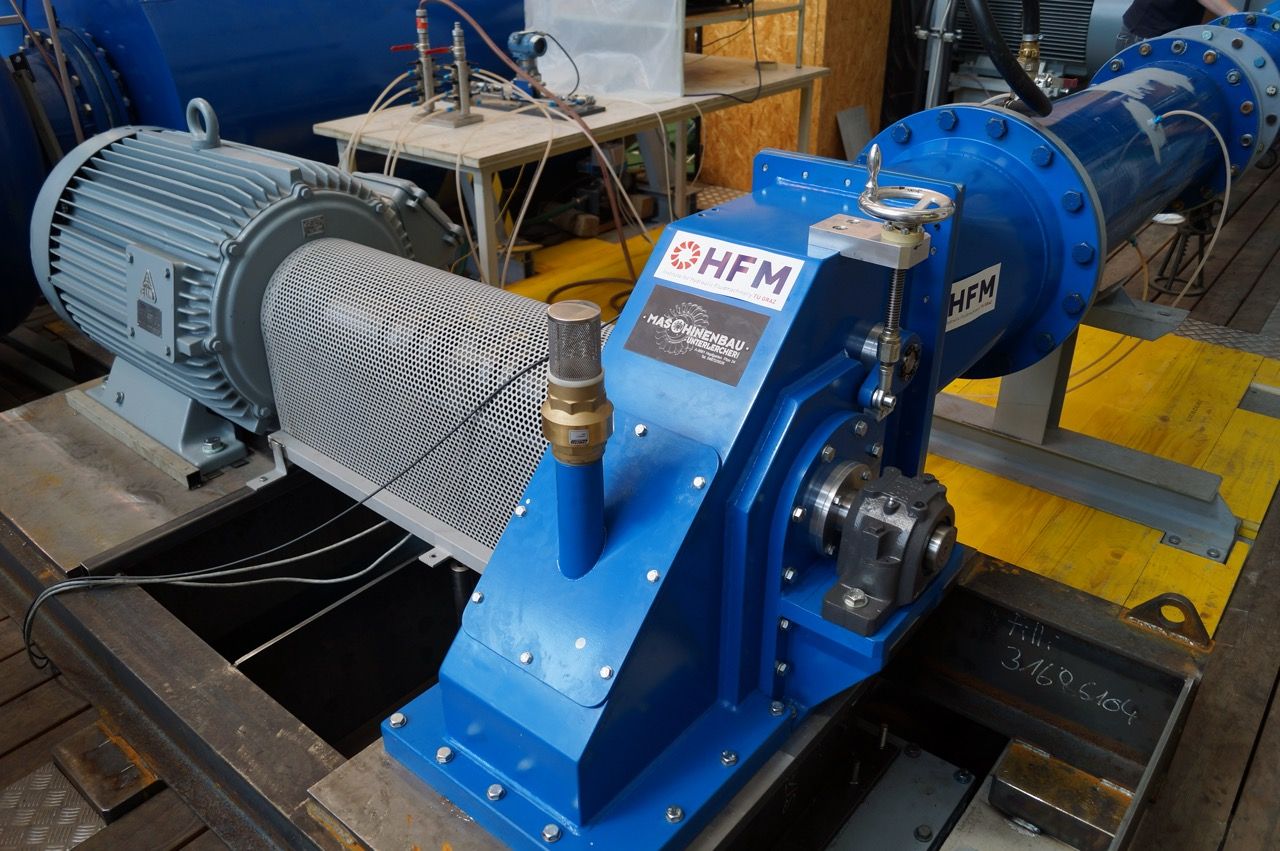

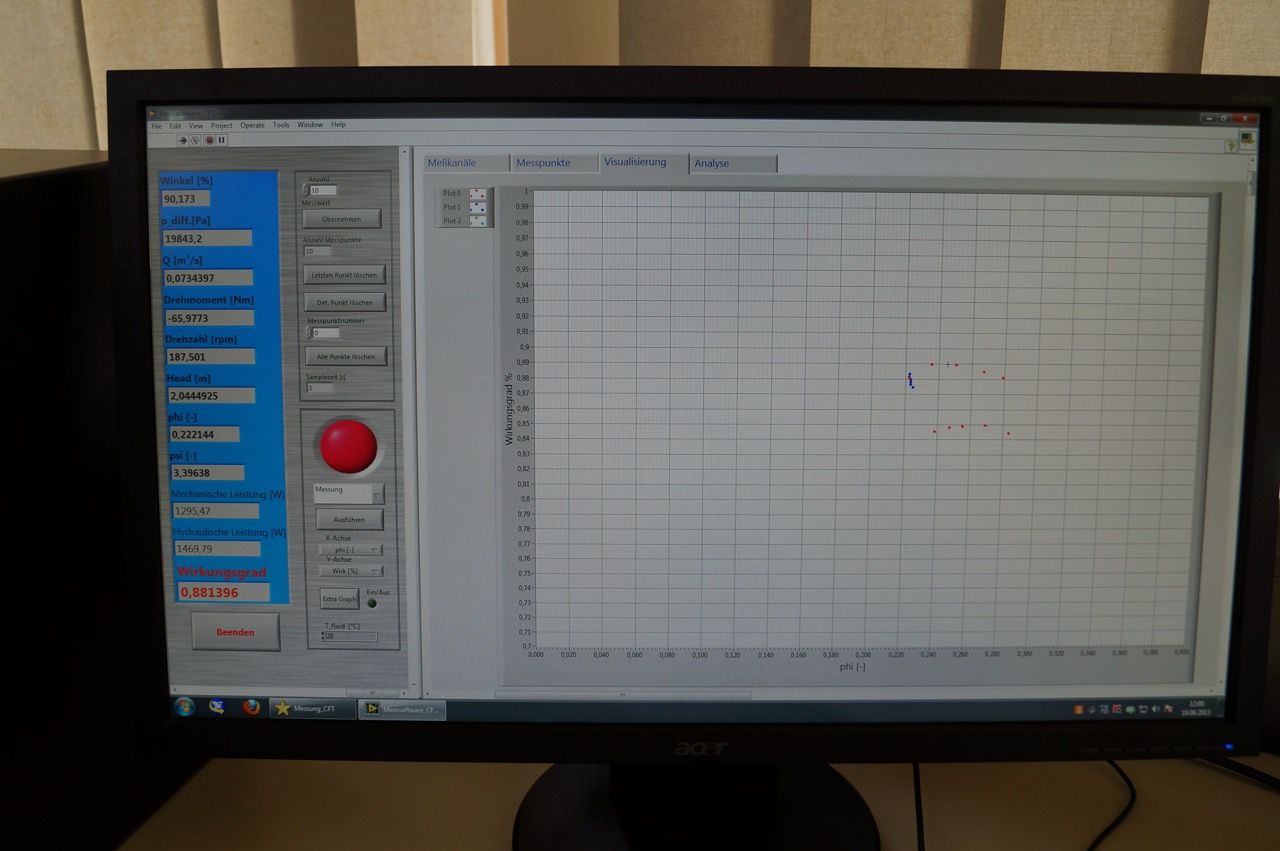

The turbine design and its geometries are precisely measured and continuously improved on our in-house turbine test bed with the appropriate measurement and control technology.

After a hydropower plant has been commissioned, it is analysed by us using characteristic curve measurements, which gives us important information about the turbine output over the entire control range.

The knowledge gained this way flows back into the design and construction of new plants.