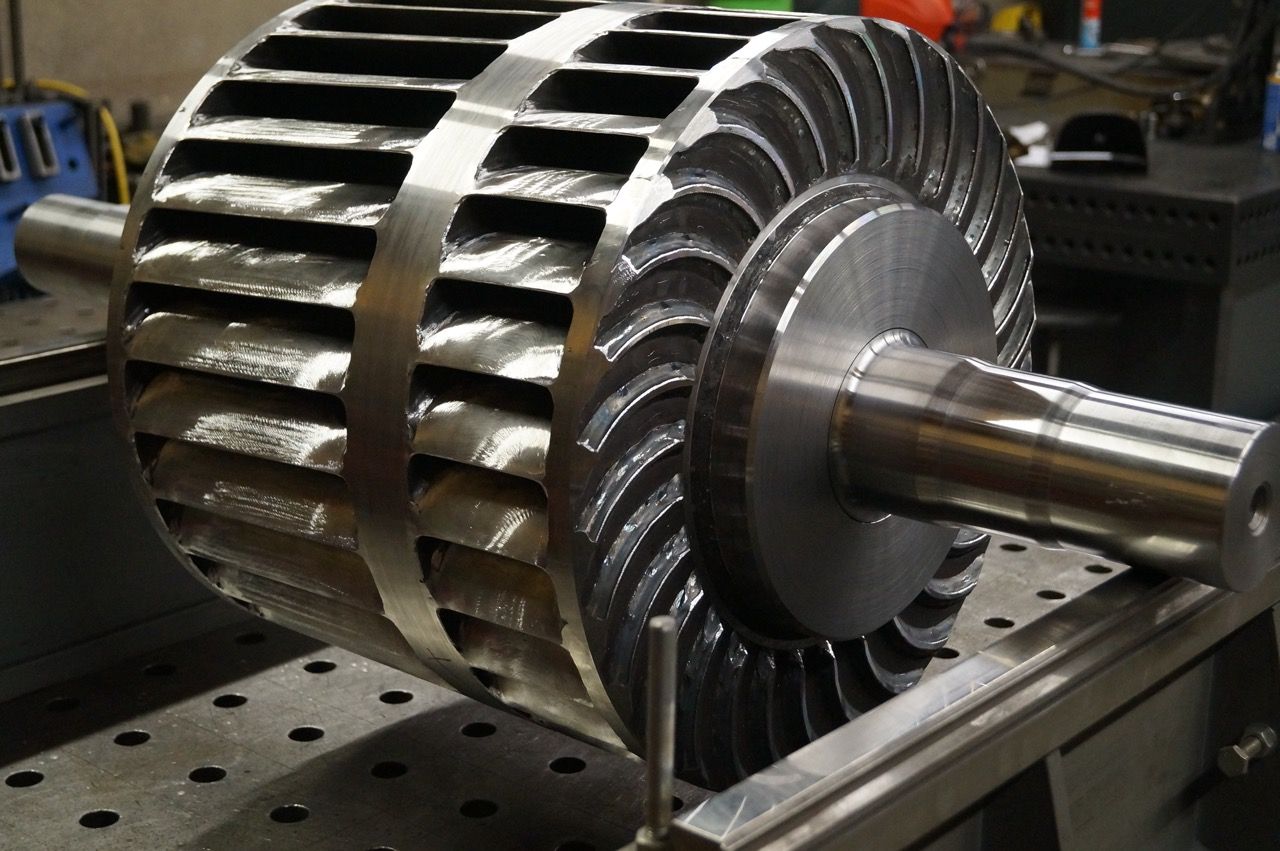

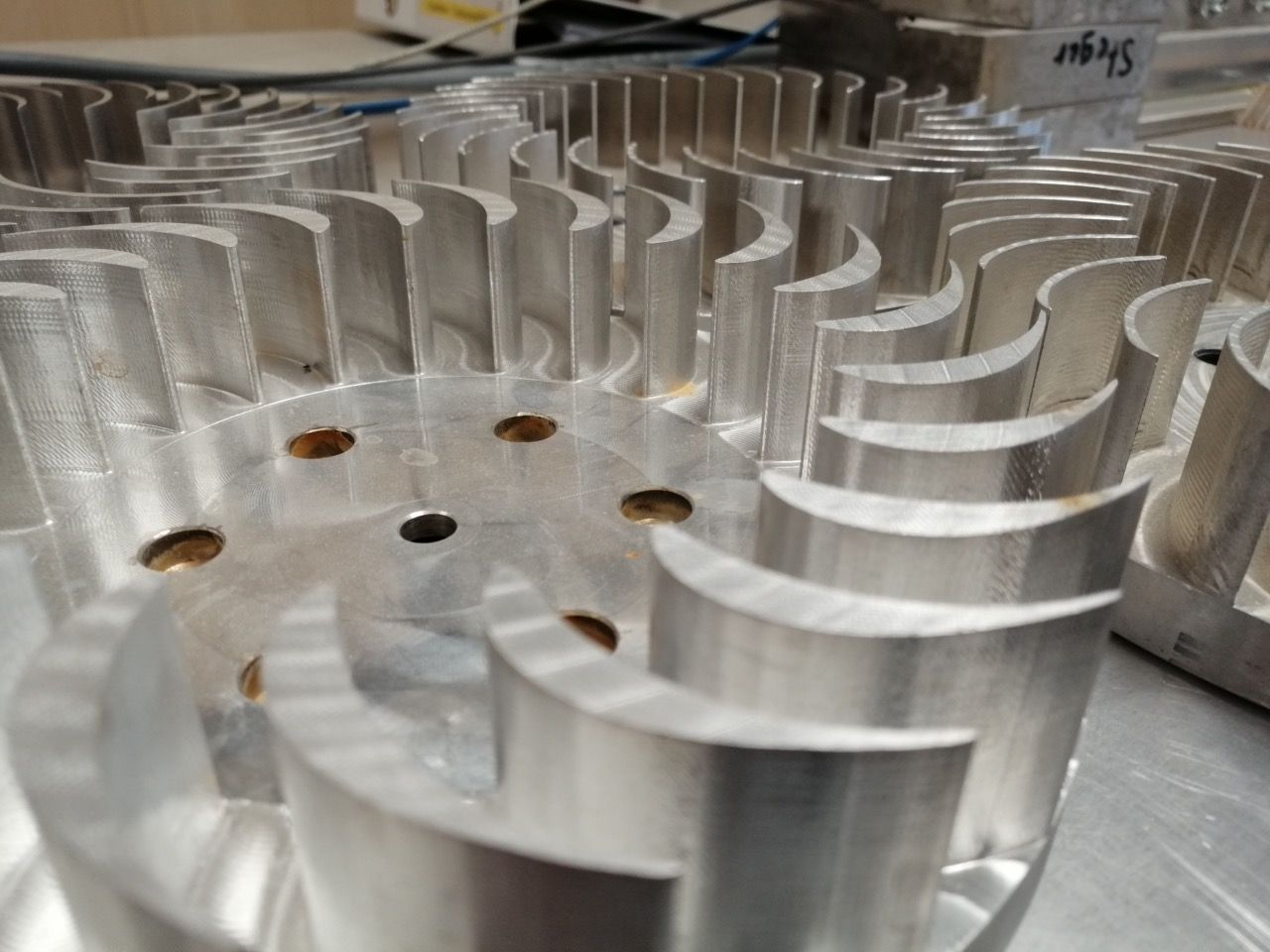

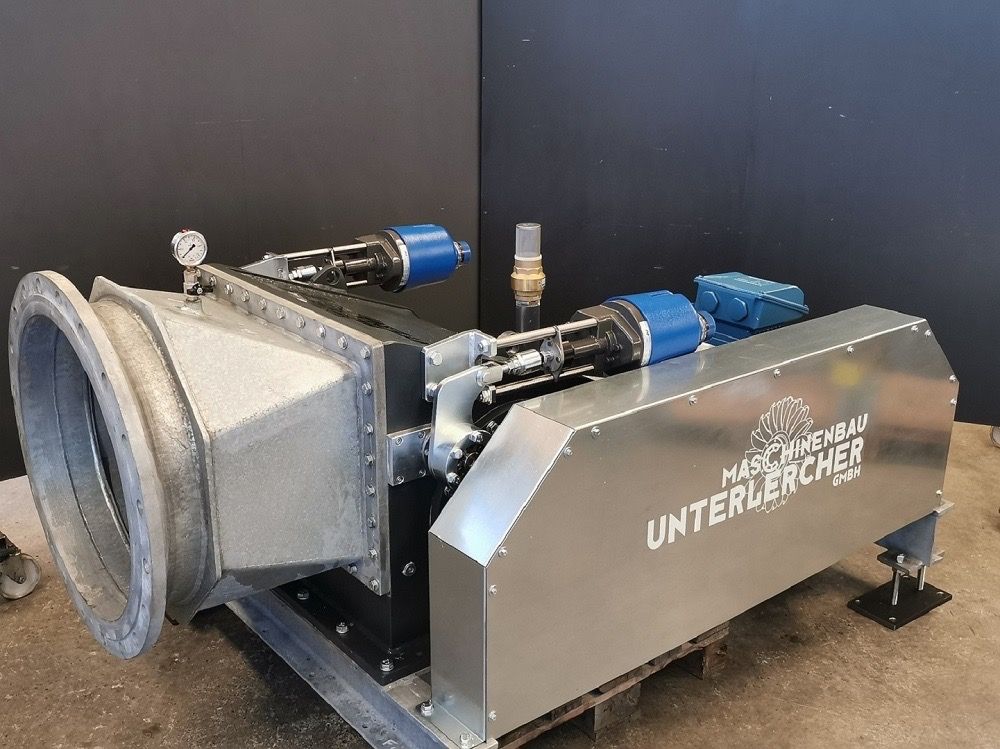

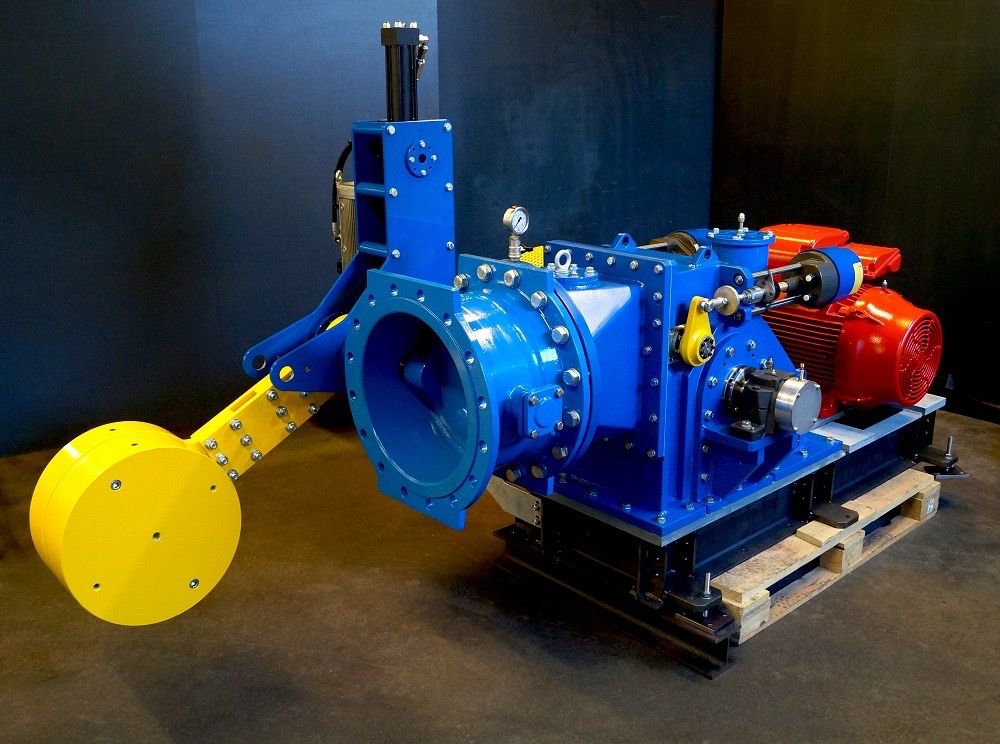

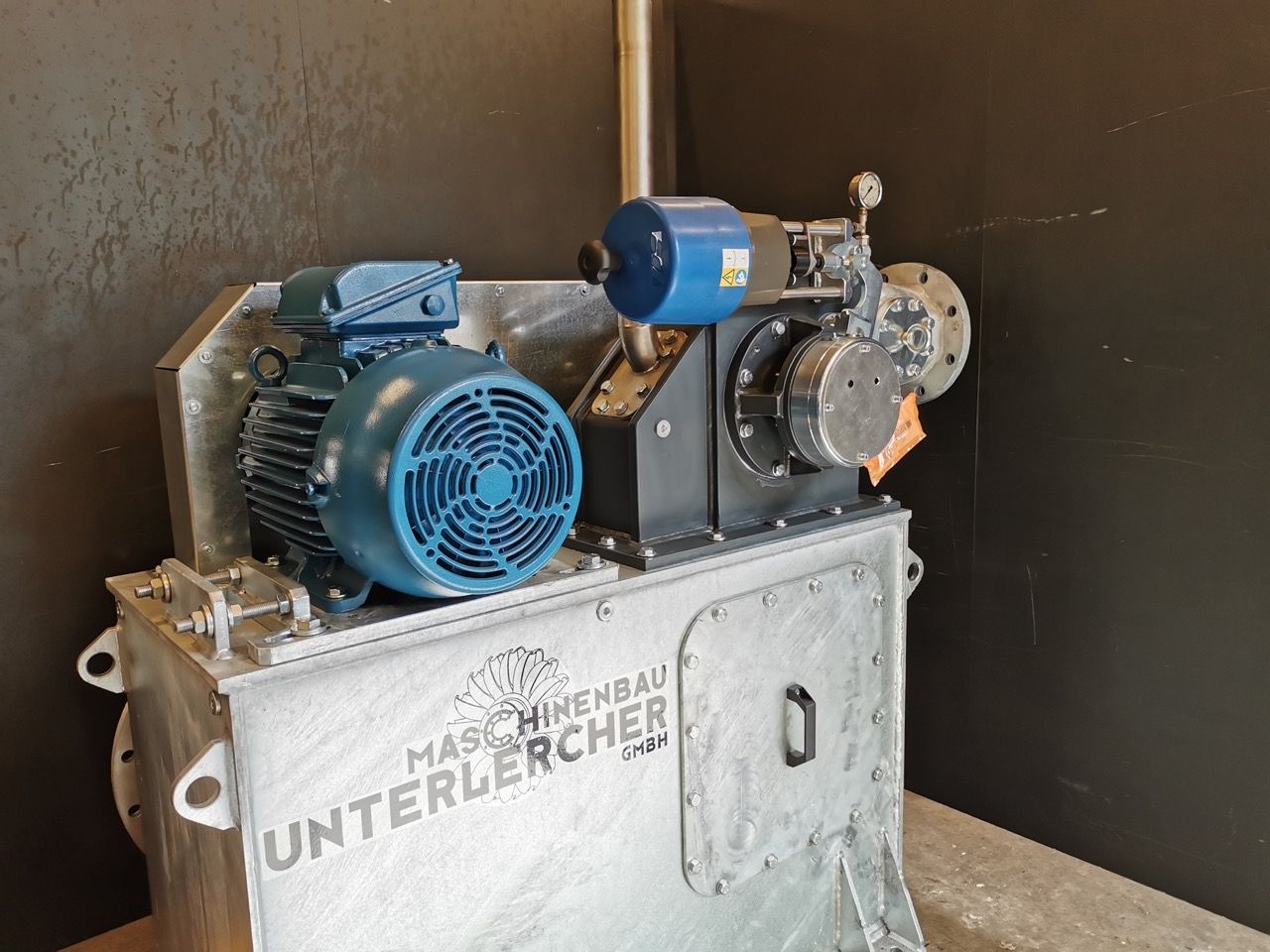

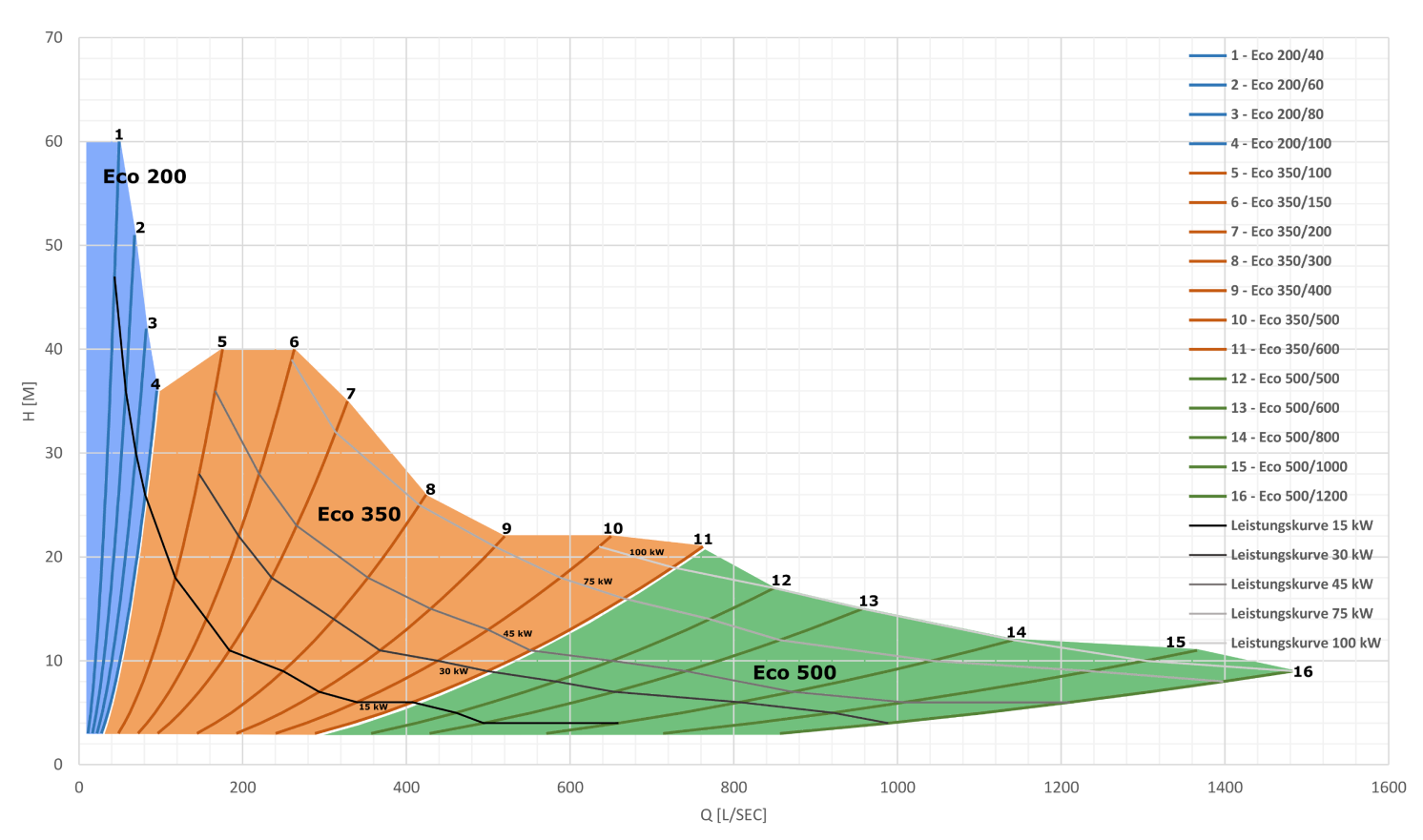

In the course of a research project cooperating with the Institute of Hydraulic Fluid Machinery of the Graz University of Technology, we have succeeded in significantly improving the fluid mechanics of the CFT turbine, which is based on the crossflow turbine principle.

The efficiency level has been significantly increased, and the partial load behaviour of the improved turbine is excellent as well.

EXPERIMENTAL INVESTIGATION OF THE CROSSFLOW TURBINE WITH A DRAFT TUBE

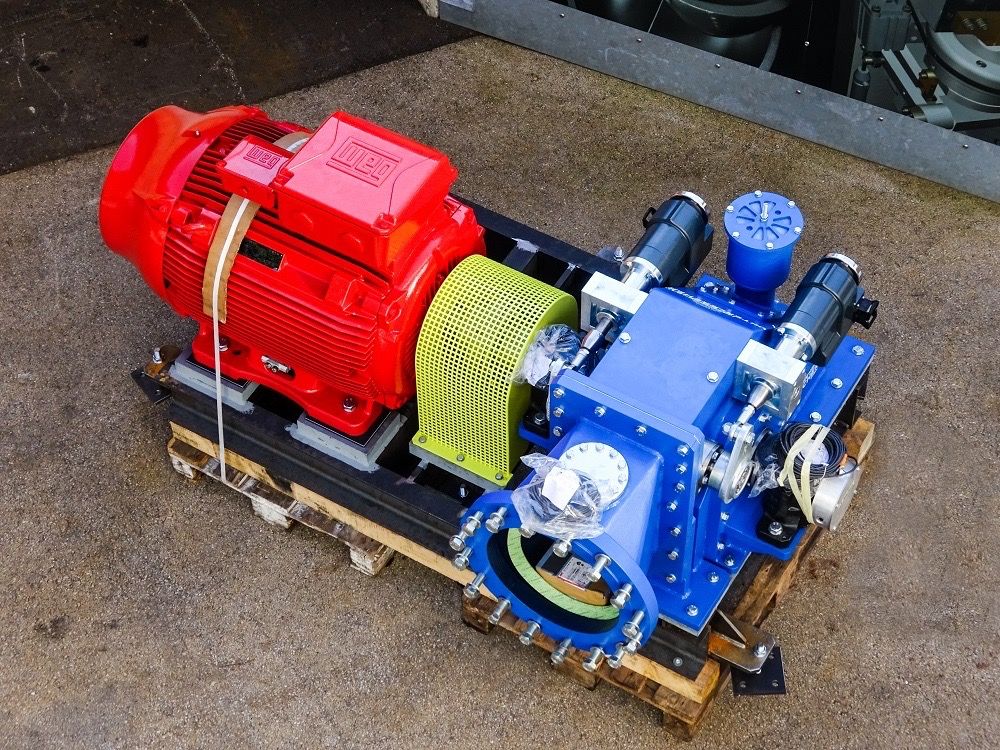

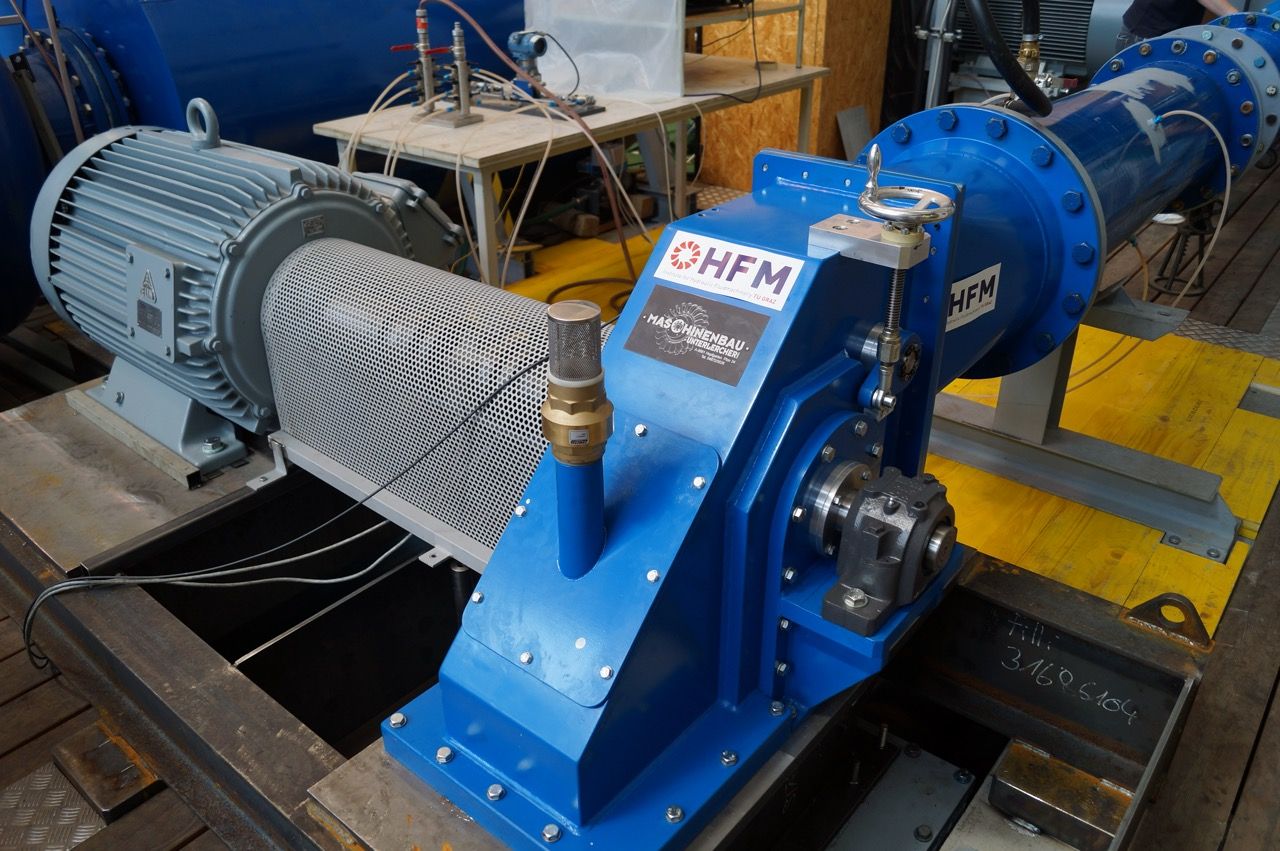

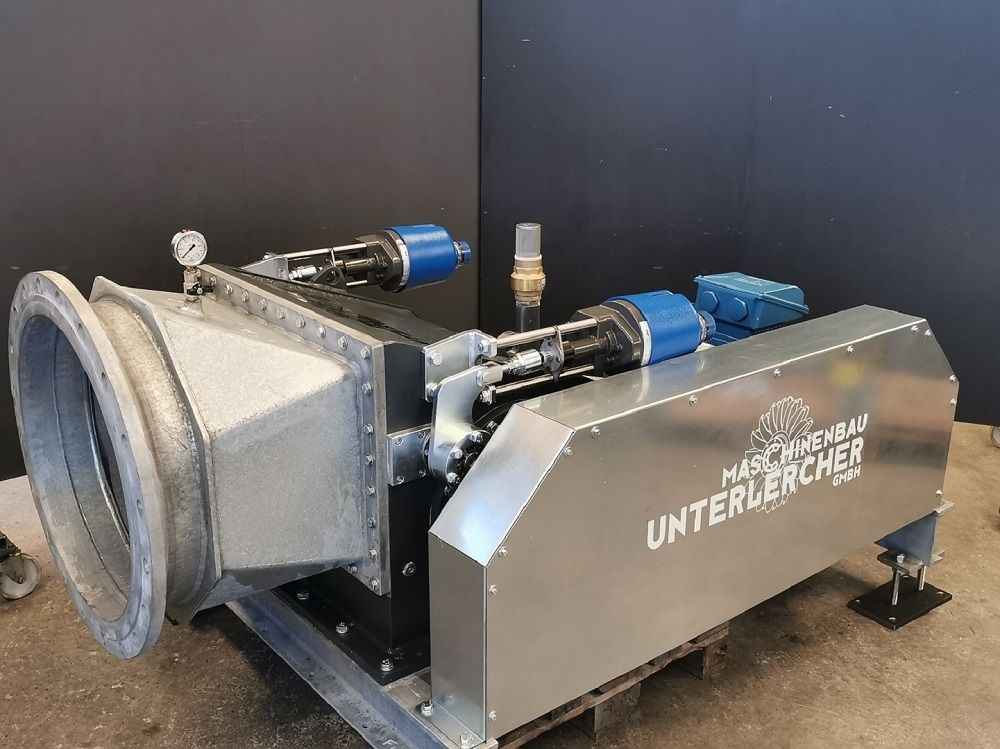

As part of a master's thesis at Graz University of Technology, our crossflow turbine was experimentally examined on an in-house test bench. The aim of this work was to precisely verify the influence of a draft tube and also to compare different draft tube shapes with each other. It was shown that the use of a draft tube leads to a significant increase in performance, especially in the low-pressure range, and that a very special shape has advantages over other shapes. In addition, other very interesting findings emerged.

The data obtained allows the CFT turbines to be designed even more precisely, and optimally adapted to the hydraulic conditions of the customer's plants.